PACKAGING

PANELS

We manufacture expanded polystyrene (EPS) panels to the size you need and in different densities depending on the use.

In the packaging sector this type of product is mainly used for:

- Separation

- Compensation

- Protection

- Piling

CUTTING

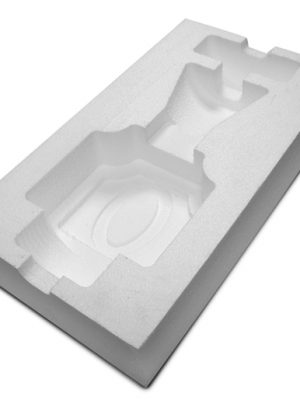

The expanded polystyrene (EPS) cutting is a pioneering technique introduced in the sector by Valero. It enables us to make pieces that up until now where only produced with moulds. Its advantages are:

- Very competitive prices (no investment in moulding is required)

- No minimum orders (short and medium series, no need of large volumes for amortisation and depreciation)

- Several for and thickness (we adjust to any need the customer may have)

- Minimum execution deadlines (once the design has been decided, manufacturing is set in place in that moment to avoid delays in the manufacturing of moulds)

MACHINING

We can adjust to our customers’ needs offering competitive prices. Our production system produces cut-to-measure pieces (so no investment in moulds is required), so we can offer you packaging services adapted to your needs, in record times and no minimum orders. Thanks to our state-of-the-art technology in machining and cutting we can offer the most precise EPS products in the market.

Some of our star products are:

- Polystyrene L edger (ideal for protecting edges and corners)

- Polystyrene U edger (ideal for protecting edges and separation between pieces)

- Polystyrene comb (for protecting and storing panels, ideal for packing ceramics)

- Special polystyrene forms (EPS cutting and machining adjusted to customers’ needs)